Waterjet Cutting Services

Large Format Waterjet & Plasma Cutting

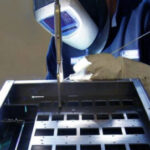

Waterjet Cutting Services

Large Format Waterjet & Plasma Cutting

Cutting any material up to 300mm thick

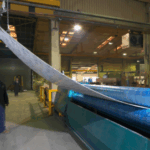

Waterjet cutting up to 7.3m x 2.4m x 200mm or 4m x 3m x 300mm

Plasma cutting up to 10m x 2.5m x 50mm

The UK's Largest Water Jet Cutting company

If you’re looking for a reliable water jet cutting service in the UK, WEC Waterjet is the clear choice.

As part of the award-winning WEC Group, we are one of the UK’s leading providers of abrasive water jet and plasma cutting services. We deliver precision cutting solutions across multiple industries.

We use state-of-the-art water jet cutting machines capable of cutting almost any material – including metal, composites, stone, glass, and even armoured plate.

Our water jet cutters deliver exceptional accuracy, even meeting the tight water jet cutting tolerances required in sectors such as Aerospace and Defence. Customers choose WEC Waterjet because we combine cutting-edge technology with proven reliability, fast turnaround times, and a commitment to quality.

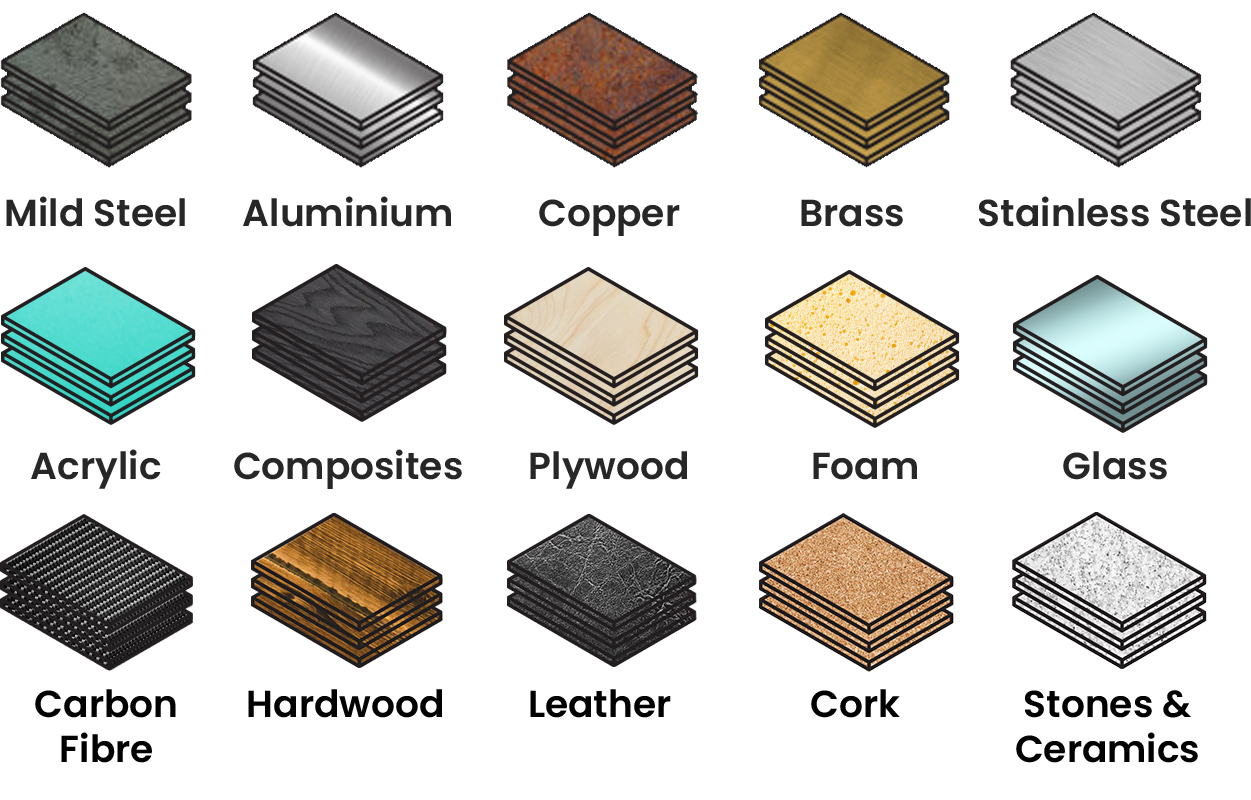

Materials

At WEC Waterjet, we offer versatile water jet and plasma cutting services suitable for a wide range of materials and industries. Our advanced water jet cutting machines deliver precise, high-quality results across a variety of metals—including aluminium, stainless steel, carbon steel, brass, copper, and more.

We also cut plastics and composites such as acrylic, Foamex, carbon fibre, fibreglass, rubber, and silicone, as well as specialist materials like glass, wood, leather, ceramics, granite, and marble.

Many ask, “What can a waterjet not cut?” The answer is very little. Only a few materials like toughened glass or layered composites with air pockets pose limitations. For nearly everything else, WEC Waterjet provides reliable, accurate cutting up to 300mm thick.

Waterjet & Plasma Cutting Capabilities

WEC Waterjet is equipped with some of the most advanced waterjet cutting machines in the UK, including the newly commissioned Mach 500, one of the fastest and most precise machines on the market today.

Thanks to a recent £350,000 investment, our cutting capabilities have expanded to accommodate larger components up to 3m wide and 300mm thick, ensuring exceptional accuracy, speed, and versatility across all materials.

Flow Mach 500

Max 4m x 3m x 300mm

Flow Mach 300

Max 7.3m x 2.4m x 200mm (any material, or 300mm aluminium)

Flow Mach 300

Max 4m x 2m x 200mm (any material, or 300mm aluminium)

Plasma Machine

10m x 2.5m x 50mm Mild Steel, 30mm Stainless Steel, 25mm Aluminium

Trusted for Quality and Precision

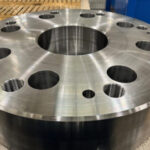

At WEC Waterjet, quality and precision are at the core of everything we do. We are fully accredited to ISO 9001:2015, ensuring that all of our waterjet cutting processes meet the highest industry standards. Our operations also comply with EN 1090 (CE/UKCA Marking), EN 3834 (fusion welding), and EN 15085 for welding on rolling stock, making us a trusted supplier for critical sectors such as rail, defence, and aerospace.

We maintain strict water jet cutting tolerances and full material traceability across every job. Test certificates are available on request, providing customers with total confidence in both our quality and our supply chain integrity.

Industries we serve

WEC Waterjet delivers high-precision waterjet and plasma cutting services to a wide range of industries, offering reliable solutions for both standard and highly specialised applications. With the capability to cut complex components from virtually any material, we’re trusted by clients across critical and heavy-duty sectors. Our advanced machinery, quality standards, and fast turnaround times make us a go-to partner for projects where precision and performance matter most.

Aerospace

Defence

Construction & Quarrying

General Engineering

Oil & Gas Industry

Offshore

Full In-House Manufacturing Support

As part of the wider WEC Group, WEC Waterjet benefits from the support of over 950 skilled staff and an extensive range of in-house manufacturing capabilities.

With access to more than 30 laser cutting machines and 200+ skilled welders along with in-house CNC machining, powder coating, sheet metal work, metal bending and folding, laser box section cutting, and bevel plasma cutting, we provide a fully integrated solution for complex projects.

Our comprehensive contract manufacturing services allow us to deliver high-quality, end-to-end production under one roof, saving time, reducing costs, and ensuring full control over quality and lead times.

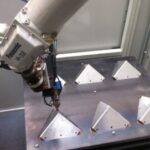

Precision Waterjet Cutting with Tight Tolerances

At WEC Waterjet, our advanced water jet cutting capabilities delivers tight tolerances, minimal material waste, and consistently smooth, accurate edges.

We offer a full range of edge quality options, from Q1 (for rapid material separation) to Q5, which provides a fine finish suitable for close-tolerance parts.

Cutting speeds are adjustable from 100% to 20%, depending on the edge finish required.

Since water jet cutting produces no heat-affected zones, it’s ideal for temperature-sensitive materials and can achieve tolerances as precise as ±0.005”, depending on material and thickness.

For faster processing of thick metals, our high-definition plasma cutting machine features full bevel cutting and true hole technology, making it perfect for large-format profiling and weld-ready components.

Fast Lead Times and Nationwide Delivery

At WEC Waterjet, we pride ourselves on our fast turnaround times and reliable service. With multiple cutting machines in-house and a highly skilled team, we can meet tight deadlines without compromising on quality. Whether you need a one-off prototype or high-volume production, we’re equipped to deliver on time, every time. Our nationwide delivery network ensures your parts arrive quickly and safely, wherever you are in the UK.

Our Services

Our wide range of modern fabrication equipment, including robotic welding, allows us to offer TIG, MIG, and ARC coded welding, as well as sheet metalwork, large machining, and heavy engineering services.